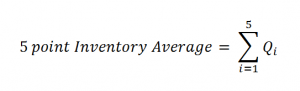

In our blog posting, Draining the Inventory Pond, one of the companies that we are familiar with has the end of quarter spikes referenced in the posting. In some of their operating units, up to 30-40% of their quarterly sales occur in the last week of the quarter. Because of this, their primary measure of inventory is what they call a “5 Point Average.” They basically average their inventory levels for the current quarter and four previous quarters i.e. five quarters. This ensures that every inventory report includes a year-end number as 20% of the calculation. This averaging also mitigates extreme pond draining which happens at year end when inventory counts the most.

where Qi=closing inventory in $$ for Quarter i with Qs being the current quarter.

There are two reasons to use the 5 Point Average:

- The end of the year extreme inventory reduction is averaged out and not allowed to dominate.

- When inventory objectives are for this kind of measure, a 5 or 10% reduction in inventory has to be achieved and sustained for over one year.

This method is not common to the point that it is hard to find references for it in inventory texts and articles.

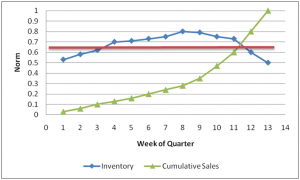

With modern ERP systems, another kind of Inventory Average is possible. Perpetual Inventory can be reported at the end of each day. Perpetual Inventory is the running tally of inventory before the end of period accruals and reserves. Perpetual Inventory is inventory that the Supply Chain most directly controls. ERP systems can report the Average Daily Inventory by month and quarter. Average Daily Inventory is more representative of what really happened in the period. The red line on the graph below represents the average quarterly inventory for our example company.

Reducing the daily average or the week 14 end point over 5 Quarters will have the same kind of result, inventory will have been lowered. It will have been lowered for more than a year and most likely be sustainable.

The caution here, however, is NOT to rely on achieving this by draining the pond even more. The likely drop off in customer service will be noticeable to the customers. If the customers are big and sophisticated, such as Wal-Mart, the penalties and other pressures to improve service will put an end to excessive draining well before the reductions will show up in a 5 Point Inventory Average.

The higher the quarter end peaking:

- The greater the need to drain the pond

- The greater the temptation to over drain the pond

- The greater the impact on Customer Service

The obvious path of action here is then to simply eliminate month end peaking. It is incredibly simple to say and even craft into a strategic objective. Making it happen? That is a different matter altogether. It rarely happens. The customer base is too well trained.

Is inventory averaging right for you? Are you draining the pond enough? Too much? Let us know your experiences good and bad.