I am proposing another similar mindset. This one is entirely of my own creation: Optimal Thinking. I think it is of equal importance.

Naturally, everyone would like to think optimally. It would be great to have our minds razor sharp and operating at peak efficiency with flawless logic. But, this is not what I am talking about. By Optimal Thinking, I am talking about a conceptual understanding of multi-criteria constrained optimization and its role in our everyday activities, particularly in business.

To illustrate the point in a real life example unfolding as I write this, imagine you are an auto manufacturer. Your reputation and name is synonymous with quality. Quality and Reliability have always been what you are known for. In recent years, there has been a tremendous pressure on all in the industry to contain and reduce costs. Reputation and heritage aside, the same pressure hit our company and we have had to cut and trim. We have had to pressure our suppliers to do the same. We may have gone too far and traded off minimizing cost at the expense of quality. We are now faced with very expensive and reputation damaging recalls. This is an optimization problem with just two objectives.

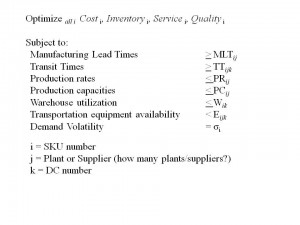

In our popular webinar series, Supply Chain Physics, we outlined the problem we are perpetually trying to solve in Supply Chain Management. The goal is to optimize Inventory, Service, Quality, and Cost subject to all the many constraints of space, capacity, production rates, etc. The model can be quite complex. In fact, they are so complex it is practically impossible to actually be able to write the equations. Even if we could formulate the problem, the coefficients and constraint boundaries are continually changing as the suppliers, production locations, equipment, product offerings, currency exchange rates, (there is almost no end to the list) constantly change and evolve over time.

We deal with this every day. We err on focusing too much on inventory and service suffers. We believe that increasing inventory will help solve our service issues. We end up playing Supply Chain Whack-a-Mole chasing these objective variables one at a time, when in fact they are co-dependent. We know what optimal is when we are looking at one variable. We want to minimize inventory and cost while maximizing service and quality.

We deal with this every day. We err on focusing too much on inventory and service suffers. We believe that increasing inventory will help solve our service issues. We end up playing Supply Chain Whack-a-Mole chasing these objective variables one at a time, when in fact they are co-dependent. We know what optimal is when we are looking at one variable. We want to minimize inventory and cost while maximizing service and quality.

Maybe all four can move in the desired direction for awhile. This is often the case when we first begin our improvement efforts. Most of our organizations are way beyond that point. This is also the case when there is a radical disruption in the marketplace e.g. the economic meltdown we experienced in October 2008. But after a point, we get to an efficient set, a kind of optimization isobar where the only improvement of one variable is at the expense of the others.

We need to have an appreciation of this kind of optimization, a feel for it. We need to have Optimal Thinking just like we need to have Statistical Thinking. In Statistical Thinking, we need a feel and appreciation for the variation inherent in all the information and data we look at as we make our business decisions. The same holds true in this proposed concept of Optimal Thinking. What are our objective functions? What are our constraints? What are the tradeoffs?

What is our operational definition of Optimal Thinking?

We are faced with countless decisions each day in our personal and business lives. We try to make the best decisions. Optimal Thinking is a way of looking at decisions to:

- Realize the various entities or objectives we want to be maximize or minimize

- Evaluate the trade-offs between these various objectives and choose the best mix of max and min for the situation

- Acknowledge and account for limiting factors or constraints that may be in play.

Putting it all together: How do we make this work? How do we put this kind of thinking, both statistical and optimal, into play?

I recall a definition of Operations Research as “the science of informed decision making.” I studied Operations Research and have read many Operations Research and Industrial Engineering papers extolling sophisticated optimization models for any variety of business applications. I came to the conclusion that while the models were interesting, it was close to impossible to have the data to quantify most of these sophisticated detailed models and drive the intricate equations. But they nurtured a sense of Optimal Thinking.

Back in the real world, we still have to make decisions every day. They have to be made in time frames dictated by the business cycle. What do we plan to sell? To whom? Based on this how much inventory should we carry? And where should it be placed or staged? These decisions have to be made to get the right products in the right quantities to the right places. Sometimes we rely on our intelligence, insight, and experience. We rely on a combination business knowledge and both statistical and optimal thinking to make these decisions. We have all seen the rare brilliant leader or analyst whose skills in this regard are razor sharp. These rare individuals have a heightened sense of both Statistical and Optimal thinking and are uncanny in their abilities. Often, others try to emulate this kind genius and just end up shooting from the hip and missing the mark way too often. This kind of true genius and brilliance is a far rarer commodity than we are led to believe.

The most useful modelers back off and ask what data is available? Is the available data reliable and useful? How should the variability in the data be treated? What models and formulae can we use to make the best decisions with the data and variability of the data we have? How can we optimize our decisions given the data we have and within the time frames we must operate. This is the fundamental thinking we employ at DemandCaster. We have designed our DemandCaster software to use solid reliable operations data and use proven models. We know that our model helps nurture both statistical and optimal thinking in our clients.

Statistical and Optimal thinking are needed when we use software tools to do the calculations and make recommendations. We need a sense of when variation is significant and the trade-offs and constraints that rule the decision space we live in. This allows to better interpretation of the output of software tools and models. We may or may not fully understand the intricacies, mathematics, statistics, or engineering of the software tools and models, but statistical thinking and optimal thinking will go a long way to assist us in this regard.

There is in implicit feeling that these kinds of thinking can be learned and honed over time. We fully believe that and have seen such in our work. We have been nurturing these concepts without having named nor defined them. With operational definitions of these concepts, we believe we will be even more effective. First, one must be aware of the concept of Statistical and Optimal Thinking. These types of thinking must then be sharpened over time. Managers and leaders will then be more effective using the skills in managing the outputs of their ERPs, software tools, and models that are designed to help optimize their business decisions.